Recent leading edge catafalque designs demonstrate how catafalque function can be modified in innovative and flexible ways to operate in new contexts.

ROOKWOOD CATHOLIC, SYDNEY

At the end of 2015 Austeng manufactured and installed a new catafalque for Catholic Cemeteries and Crematoria’s Sacred heart Chapel at Rookwood Catholic.

This fixed catafalque was custom designed to fit into an existing pit inside the timber lined chapel. The attendant can select a half lower function where the casket just lowers from view, or a full lower function where once the casket is at the base of the pit, timber doors close up to seal off the catafalque opening.

One of the engineering challenges was the chapel and crematorium are on different floor levels with about 2.7m height difference. Once the service concludes the casket is again raised up and transferred via a transport trolley to a lift that conveys the casket to the crematorium below. From there the casket is transported via a transport trolley to a cool room or directly to the cremator charge bier. This results in successfully overcoming all of the inherent manual handling challenges.

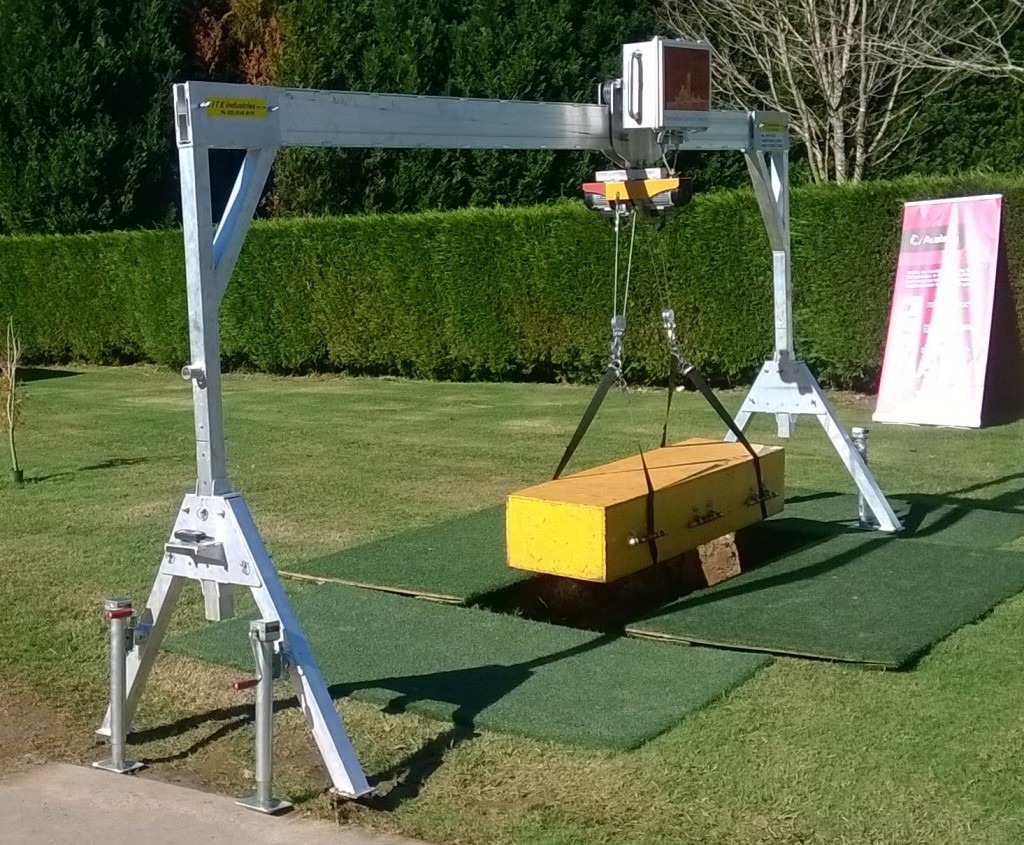

PORTABLE CATAFALQUE – BUNURONG MEMORIAL PARK, MELBOURNE

Recent extensive building works at Bunurong Memorial Park, Sandhurst have culminated in a number of reflection spaces/function rooms that can accommodate multiple community needs rather than those simply relating to traditional funeral/memorial services.

In line with this context, the specification for the three catafalques from the Southern Metropolitan Cemeteries Trust (SMCT) included not only requirements relating to leading edge innovative design and operability but also full portability whilst embodying the highest aesthetic considerations. During the consultation process, Austeng were also able to offer rendered concept images and operational sequencing animations of innovative and unusual catafalque shapes (such as ellipsoid and cylindrical) to assist in the Cemetery Board’s consideration of alternative designs.

Three battery powered catafalques were manufactured with portability provided via a battery powered tow tug. The patterned, forged glass extends upwards and provides additional screening of the casket during committal as well as providing a sense of occasion and a tangible sense of finality/interment for the mourners.

An easy to use remote control allows automated platform and glass raising/lowering sequencing. Fault detection and battery status indicators are incorporated in the remote handset.

Phil Snow SMCT Bunurong Project Manager commented “…the portability aspect adds to the versatility of our spaces. Also they are aesthetically pleasing as well as easy to operate. many funeral directors commented positively on their versatility and appearance at the Opening Day”.

VICTORIA POLICE ACADEMY – MT WAVERLEY

Victoria Police commissioned Austeng to design and manufacture a custom coffin presentation trolley for use in ceremonial funeral services for past/present Victoria Police members.

A sleek mobile timber box with integrated coffin roller deck is embellished with ‘Police Blue’ glass inserts and Bronze Victoria Police Emblems.